Learn everything about the 5S quality method and work more efficiently and effectively. Do you want to implement the 5S quality management technique in your company, but you are not sure how to get started? Then count on G&P Quality Management. Our 5S consultant will explain in detail how to achieve and maintain the 5S method.

5S

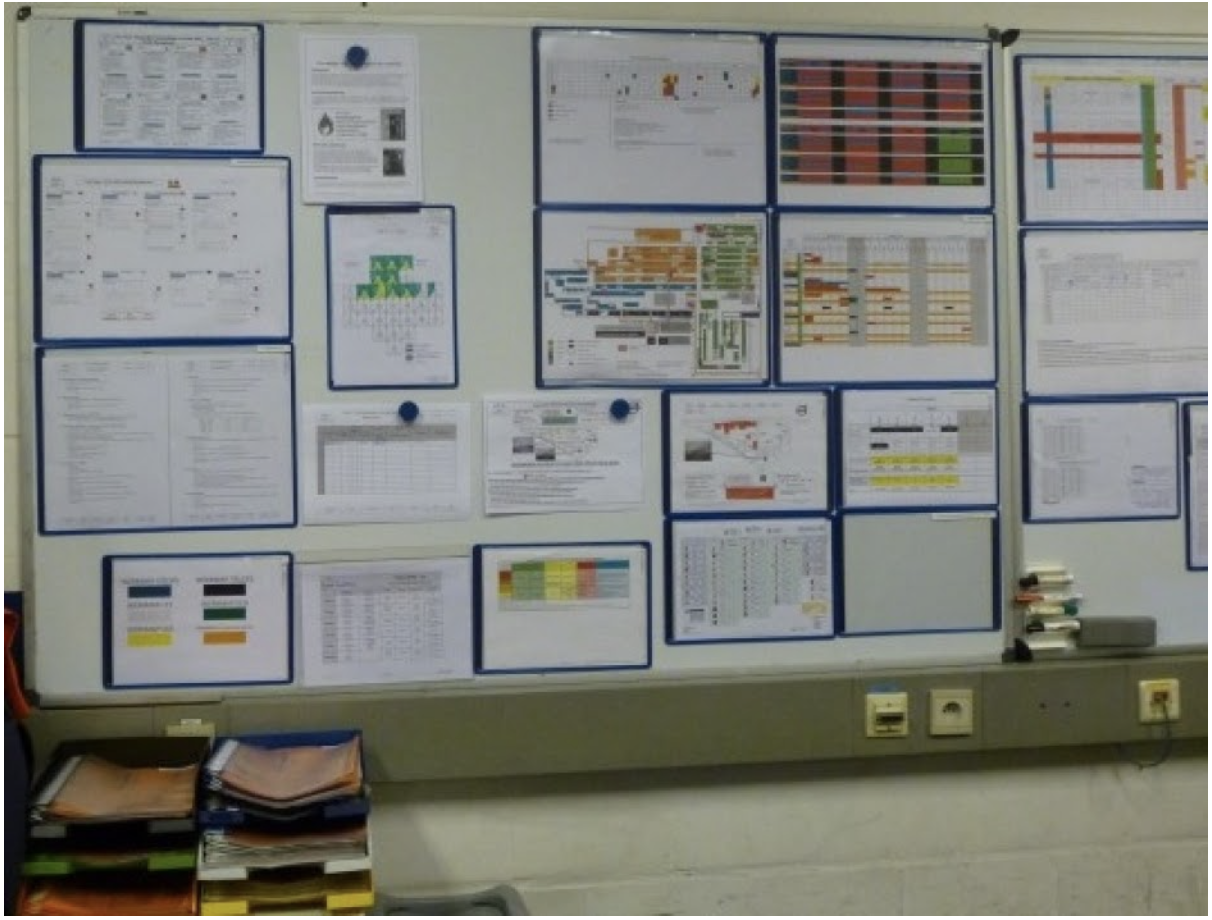

Clean and tidy

5S is a Japanese quality system developed at Toyota. The starting point is that a clean and organized workplace is a basic requirement for an optimal production process and continuous improvement. In a well-organized and clean workplace, every employee always finds everything he or she needs to do his or her job correctly, and therefore less time is lost. In other words: to work effectively and efficiently. This will automatically result in less variation and make performance more predictable.

Keep everything running

In addition, the material flow must be logical and continuous, so that displacements are minimal. Under this heading, our 5S consultant will also introduce you to bottleneck management. The aim is to ensure that your most important machines and installations never grind to a halt.

Take advantage of all the benefits

Contact us today for an appointment with a consultant and develop the 5S methodology within your company. The result? Greater productivity, lower costs, continuous improvements and more engaged and motivated employees.